Production line maintenance

Production line maintenance concerns not only current and major repairs, but also inspections, upgrades, repairs and maintenance. It includes a full technical service, which is provided by our company. We handle both the maintenance of production lines built by us and those from other manufacturers. We ensure the supply of high-end consumables and modern components from recognised manufacturers. They improve the operation of machines and entire automated workstations. We place great emphasis on modernising our clients’ industrial lines so that they are continually recognised as state-of-the-art, efficient, safe to operate and trouble-free. We can ensure your production facilities will operate around the clock without fault or risk of failure. By doing so, we protect businesses from huge financial losses.

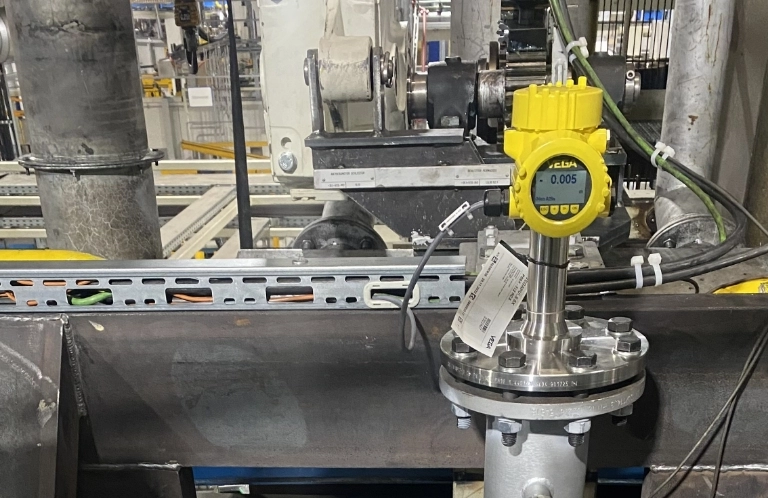

We offer a particularly wide range of products to plants with quenching lines. We are ready for their renovation and modernisation. On request, we assemble new as well as used quenching plant components: quenching furnaces, oil baths, water baths, polymer baths, transport stations with the necessary connections.

Production line relocation

We provide relocation of production lines to other plants and halls along with their reassembly, calibration and commissioning. In such cases, we also offer adaptation of machines to new technical conditions, including operation with higher-grade electrical and gas connections. Among others, we invite owners of quenching plants who want to turn them into innovative quenching stations to get in touch.